- Carbon Steel, Stainless Steel, Alloy Steel, Cast Iron.

- China

- 7 days for stock 30 days for DIY

- 80 ton/month

- T/T

- Acceptable

- Available

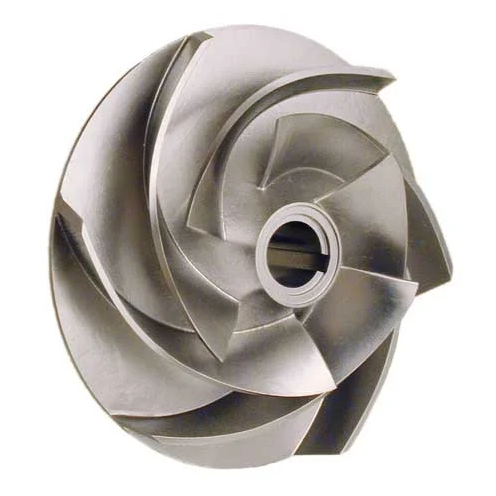

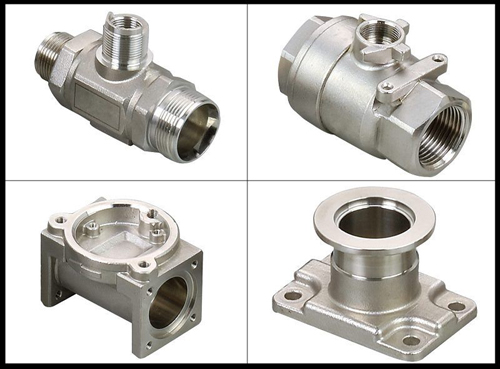

Pump and valve castings Specifications

Product Name | Pump and valve castings |

| Drawing Format | 2D drawing format: PDF or DWG (indicates technical specifications, materials, quantities, tolerances, post-processing requirements, etc.) 3D drawing format: STEP or IGS (enables a more intuitive view of product structure and dimensions, for programming purposes) |

Heat treatment | Solution treatment, Annealing, Normalizing,Quenching and Tempering, Tempering, Carbonitriding, Etc. |

Product Specifications | OEM According To Samples Or Drawings |

Finish | Passivation, Electrolysis, Shot Blasting, Sand Blasting, Electroplating, Spraying, Blackening, Phosphating, etc. |

Material | Carbon Steel, Stainless Steel, Alloy Steel, Cast Iron. |

Application | Pump and valve castings can be used to control the flow of fluids, thereby achieving control and regulation of the fluid. Pump and valve precision castings are widely used in industries such as petroleum, chemical, electric power, metallurgy, pharmaceuticals and water treatment. |

Casting Process | Siica Sol Technics With Lost-wax Process |

Certifications | Certificate/IATF16949/ISO9001/ISO14001/TUV/PED/AD2000 |

OEM | Available |

Annual Output | 2000MT |

Tooling Leadtime | 2--4 Weeks |

Delivery Time | 4--5 Weeks |

Testing methods | Visual Inspection; X-ray Testing; Ultrasonic Testing; Magnetic Particle/Penetrant Testing; Mechanical Properties Testing; Air Tightness Testing, etc. |